Thermal Decomposition Technology

Ecolomondo is a clean tech company that developed the Thermal Decomposition technology platform, TDP. This proprietary technology is based on a pyrolytic platform that converts hydrocarbon waste (scrap tires) into marketable resources: recovered carbon black, oil, gas, steel and fiber.

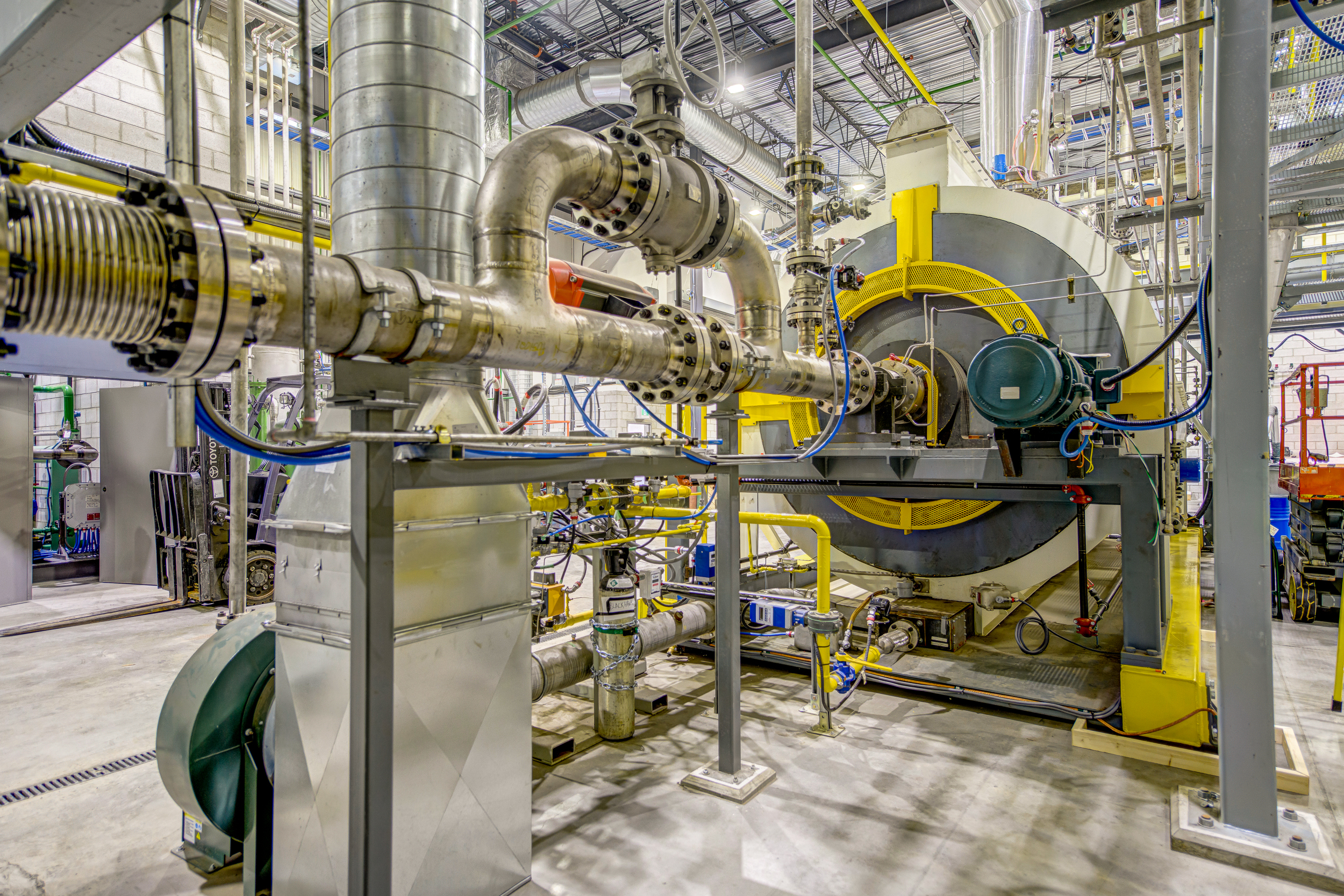

The TDP technology was developed at the company’s Contrecoeur Pilot Facility and is now being used to build TDP turnkey facilities globally. Pilot was instrumental in achieving many of the proprietary milestones such as efficient process parameters, automation, emission controls, water recycling and safety, including ensuring quality and consistency of its end-products, all needed to operate TDP turnkey facilities successfully and commercially.

Hydrocarbons are molecules that are in all products manufactured using fossil fuels. The most common types of hydrocarbon waste are tires, plastics, disposed diapers, asphalt roof shingles and automobile shred residue (ASR).

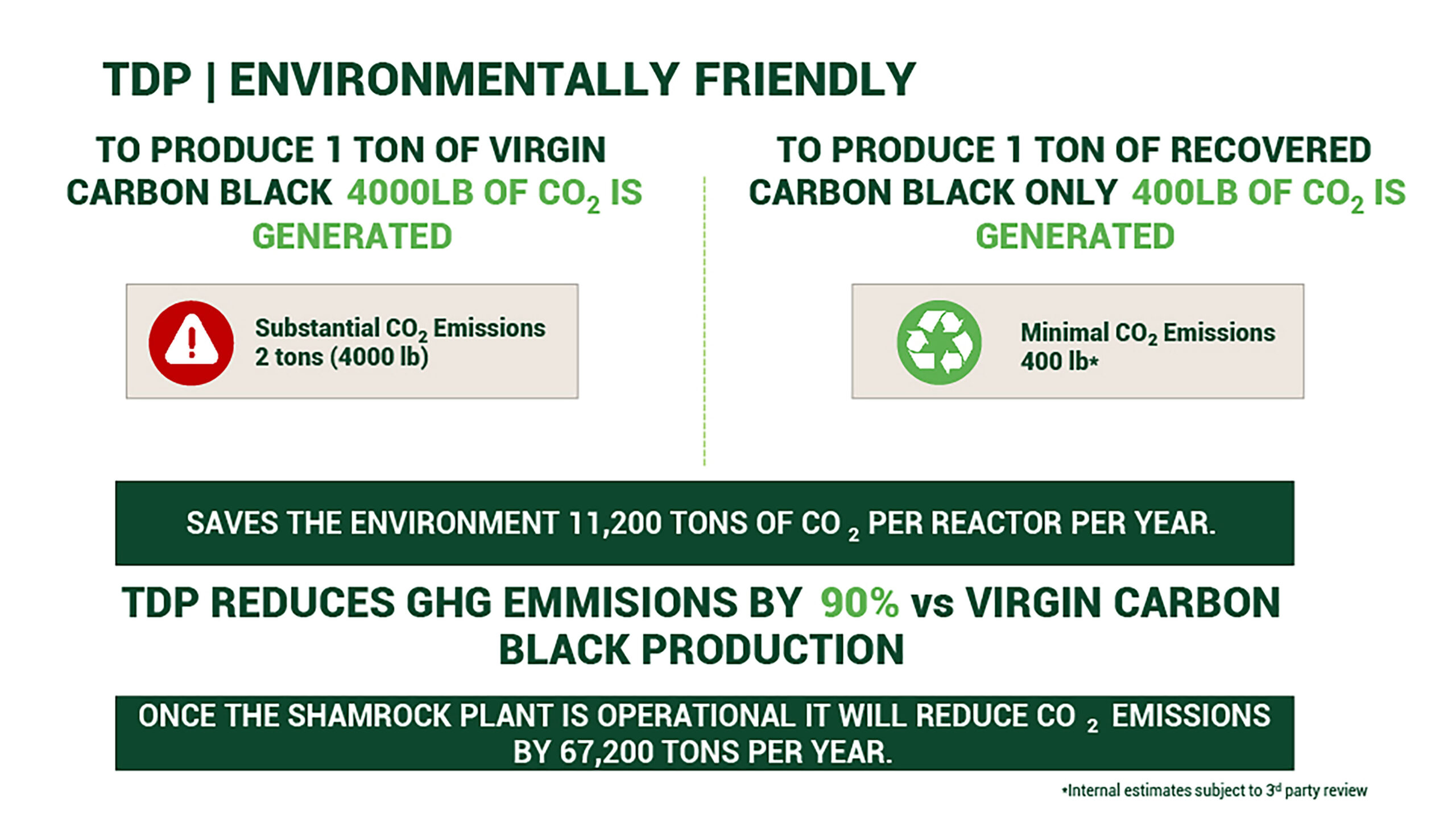

TDP creates much higher added value from hydrocarbon waste than the current methods of recycling and disposal. TDP is more sustainable and greener. The key competitive advantages that will drive TDP’s success are quality and consistency of its end-products, high quality yields that have global demand, automated system, energy self-sufficiency and high efficiency.

TDP: Safe & Green

All air measurements from stack from the TDP comply easily (much less than 10% of the specified norm) with EPA Air Emission Standards and also to each parameter specified in Environment Quebec Air Quality Standards

The solution developed by the Ecolomondo’s team of scientists and engineers is a green one. Nothing to waste! The technology is robust, safe and the products are of high quality.

Director, Institute for Chemicals and Fuels from Alternative Resources at Western University